Seeing and measuring the impossible

VIEW offers a full line of optical metrology systems for wafer, photomask, slider, MEMS, semiconductor package, HDD suspension, probe card, and micro-component process measurements.

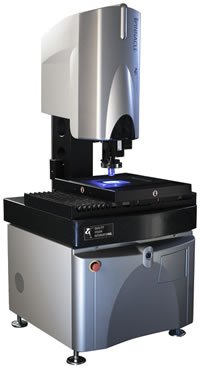

Pinnacle 250

The Pinnacle 250 offers the highest accuracy and fastest speeds of the VIEW line. Its high performance and compact footprint make it VIEW's most popular model.

The Pinnacle features a damped granite base and column, with passive vibration isolation. A precision compound X-Y stage with high-speed linear motor drives provides velocity of 400 mm / sec and acceleration of 1000 mm / sec2. This combination of high acceleration and high velocity enables the high throughput required for near-line process monitoring. The rugged and compact design of the Pinnacle lends itself to installation in either a Q/A lab or at an inspection station in the manufacturing line.

- VIEW Metrology Software (VMS™) which offers a wide array of standard measurement tools as well as a built-in scripting language to enable custom-functions.

- Elements® CAD-to-Measure software provides automatic.

Key Features and Options

The Pinnacle is ideal for measurement of small, close tolerance parts, particularly parts with a high density of features, such as hard disk drive suspensions, printer heads, precision stampings, leadframes, ball-grid arrays, and chip scale packages.

The Pinnacle can be equipped with an optional through-the-lens or offset mounted laser for added flexibility in Z-axis measurements. Pinnacle models can also utilize the optional SpectraProbe™ offering sub-micron Z-axis measurement resolution.

| Standard | Optional | |

|---|---|---|

| X,Y,Z Travel | 250x150x100 mm | 624x624x200 mm |

| Load Capacity | 25 kg | |

| Imaging Optics | Dual magnification, fixed lens | Single magnification, fixed lens |

| Metrology Camera | 1.4 megapixel, 1/2 inch, digital monochrome | 1.4 megapixel, 2/3 inch, digital, monochrome 2.0 megapixel 1/2 inch, digital monochrome |

| Illumination | All LED coaxial through-the-lens surface light and below-the-stage back light | Multi-color programmable ring light Grid autofocus system |

| Sensor Options | Through-the-lens (TTL) laser Spectra Probe white light range sensor Off-axis triangulation laser | |

| Measurement Modes | High Speed Move and Measure (MAM) | Continuous Image Capture (CIC) |