Jominy End Quench Apparatus

With in-depth domain expertise, we offer our clients a superior quality range of Jominy End Quench. These are known for their quick transfer of specimen to quenching fixture. All this is done within the specific time. Moreover, these also have features like reliable performance, longer service life and optimum functionality. These can also be availed as per the customized specifications provided by clients. Designing of quenching fixture is done as per specifications like 46' angle of top plate, jet stopper release just before quenching, quenching distance etc. Specifications and features: Motorized Water circulation through water pump with storage and test tank At a time one Jominy test can be carried out Fully covered set up with top.

Muffle Furnace

With an aim to fulfill variant requirements of our prestigious clients, we bring forth a comprehensive spectrum of Muffle Furnace. The muffle furnace offered by us is used in craft, industrial and scientific laboratory settings. This muffle furnace is developed by our workforce using finest material in accordance with set standards. Furthermore, we provide our muffle furnace in numerous customized options to meet the varied needs of clientele.

Features:

- Application specific design

- Excellent capacity

- Long working life

- Ceramic Based

- Temperature upto 1100 degree C

- PID controller, Auto Off

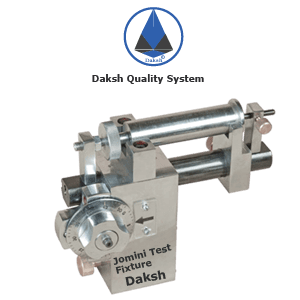

Jomini Test Fixture

The most commonly used method for determining hardenability is the end quench test developed by Jomini and Boegehold. The details of the test are covered in IS : 3848 – 1981 and ASTM A 255.

- In this test a normalized 25 mm diameter and 100 mm length test sample of steel to be evaluated is heated uniformly to its austenitizing temperature. The specimen is then removed from the furnace and placed heated uniformly to its austenitizing temperature. The specimen is then removed from the furnace and placed

- After end quenching, longitudinal Flat Surfaces are ground on opposite sides of the test piece as per dimensions. This grinding is very important for correct positioning of the sample in the fixture and also for accurate repeatable and reliable test results.

- Jomini Test Fixture is to be positioned on the main screw of the hardness tester for checking hardness of the test sample. Hardness at equal intervals (1 mm or 1/16”) to be checked and noted. Plot the resulting data on graph paper with hardness value as ordinate (Y axis) and distance from the quenched end as abscissa (X axis). By comparing the curves resulting from end quench tests of different grades of steels, their relative hardenability can be established. Thus the flatter the curve, the greater the hardenability.